Was at a short

bootcamp regarding

making and 3D printing at MIT.

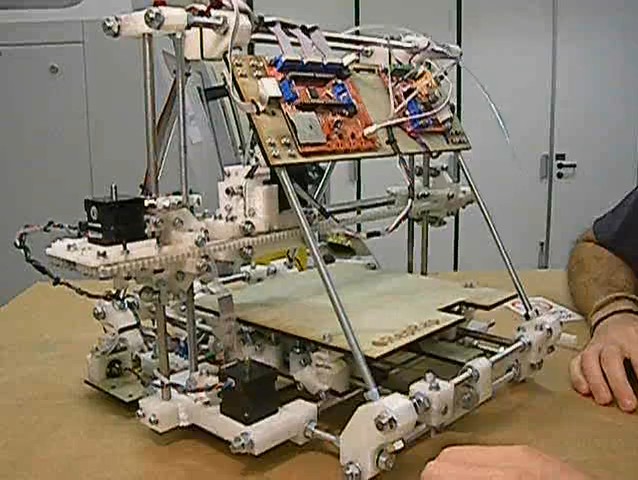

The introductory presentation was very direct. Context: subtractive (cutting) and additive manufacturing contrasted. Then the types of additive described... including...

3D printing. There are many resources from which to get your fill of details regarding 3D printing.

The panel discussion was great - if somewhat MIT project and offering centered. But why not? The event was hosted at MIT after all. And there are indeed some great offerings from MIT or started at MIT... There are too many to list.... but

Hint:

Edgerton Center Saturday Thing.

Hint:

Fablabs.

Hint: Affiliated

hackerspaces.

One panel question stood out in my mind. To paraphrase:

What is needed to make 3D printing (

CAD making) go forward (more quickly)?

And the answer was two fold....

- Better materials (and materials science).

- Simple design environments (aka design software).

The panelists and audience generally seemed to agree.

The issue is how to make it easy for anyone to design 3D objects. Maybe said "environment" will be an evolutionary step from existing CAD design tools? Maybe something revolutionary will come?

It is not exactly "design", but

design market places (or sharing places) are already starting to make things easy. The paradigm parallels "there is an app for that" taking it to "there is a model existing for that" and maybe the best design is little to no design at all, but more modification or

mashups of existing designs.

3D printing has an interesting landscape. The small players are abundant. From

printers or machines to

makerspaces to

environments.

But larger players are starting to notice.

Solidworks (Dassault) seems to be trying to be what is needed.

Autodesk:

Spark Ember,

Autodesk 123D, spaces in

San Francisco and

Boston.

It was mentioned in passing that it is unclear what people want to create. And in many cases a created object failure sours people to the technology. Maybe the area is waiting for a "killer model" for people to create? Have heard it kicked around that most people print

phablet cases, trinkets or parts for printers. And there are

always "

issues".

Toys always seem a good place to start. How about adapters for various sizes of

construction blocks? They largely already work by allowing larger series to stack on smaller series. What one really needs is to go the other way. To allow smaller details to be affixed to larger constructs (based on larger units). Project from

F.A.T. (warning - unfortunate acronym).

Like this Lego Duplo Primo

adapter or

kit.

.jpg)